Innovative Technology Allows for Electric Bending in Construction Projects

By:Admin

With its state-of-the-art electric actuation system, Electric Bending offers several advantages over traditional hydraulic bending methods. The precision and speed of the electric system enable more accurate and efficient bending of metal components, resulting in higher quality finished products. Additionally, the electric system drastically reduces energy consumption, making it a more sustainable and environmentally friendly option for industrial manufacturing.

One of the key benefits of Electric Bending is its adaptability to various metal materials, including aluminum, steel, and copper. This versatility makes it an ideal solution for a wide range of industries, from automotive and aerospace to construction and infrastructure development. By allowing for precise and reliable manipulation of different metals, Electric Bending opens up new possibilities for manufacturers to create complex and innovative metal components.

The company behind this groundbreaking technology, a global leader in industrial automation and advanced manufacturing solutions, has a long-standing reputation for pushing the boundaries of what is possible in the field of industrial engineering. With a strong focus on research and development, the company has consistently been at the forefront of innovation, developing cutting-edge technologies that have revolutionized the way businesses operate and produce.

In addition to Electric Bending, the company offers a comprehensive range of advanced manufacturing solutions, including robotic automation, additive manufacturing, and digital transformation services. By combining expertise in these areas, the company is able to provide integrated solutions that optimize production processes, improve product quality, and reduce manufacturing costs.

The development of Electric Bending is a testament to the company's commitment to driving innovation in the industrial manufacturing sector. By leveraging its expertise in electric actuation technology and materials science, the company has succeeded in creating a game-changing solution that has the potential to reshape the metal bending industry.

The impact of Electric Bending is expected to be far-reaching, with manufacturers across various industries poised to benefit from its advanced capabilities. By streamlining and enhancing the metal bending process, Electric Bending has the potential to drive significant improvements in productivity and product quality, ultimately resulting in a competitive edge for businesses that adopt this cutting-edge technology.

Furthermore, the sustainability benefits of Electric Bending are in line with the growing emphasis on environmentally friendly manufacturing practices. By reducing energy consumption and minimizing waste, Electric Bending aligns with the broader trend toward sustainable and eco-friendly industrial operations.

As Electric Bending continues to gain traction in the manufacturing industry, the company is committed to supporting its customers in adopting and integrating this innovative technology into their operations. Through comprehensive training, technical support, and ongoing maintenance services, the company aims to ensure that businesses can fully harness the potential of Electric Bending to improve their manufacturing processes and achieve their production goals.

In conclusion, Electric Bending represents a significant leap forward in the field of metal bending, offering a combination of precision, efficiency, and sustainability that is unmatched by traditional bending methods. With the backing of a leading company renowned for its expertise in industrial automation, Electric Bending is well-positioned to drive positive change in the manufacturing industry, paving the way for a new era of advanced and sustainable metal bending processes.

Company News & Blog

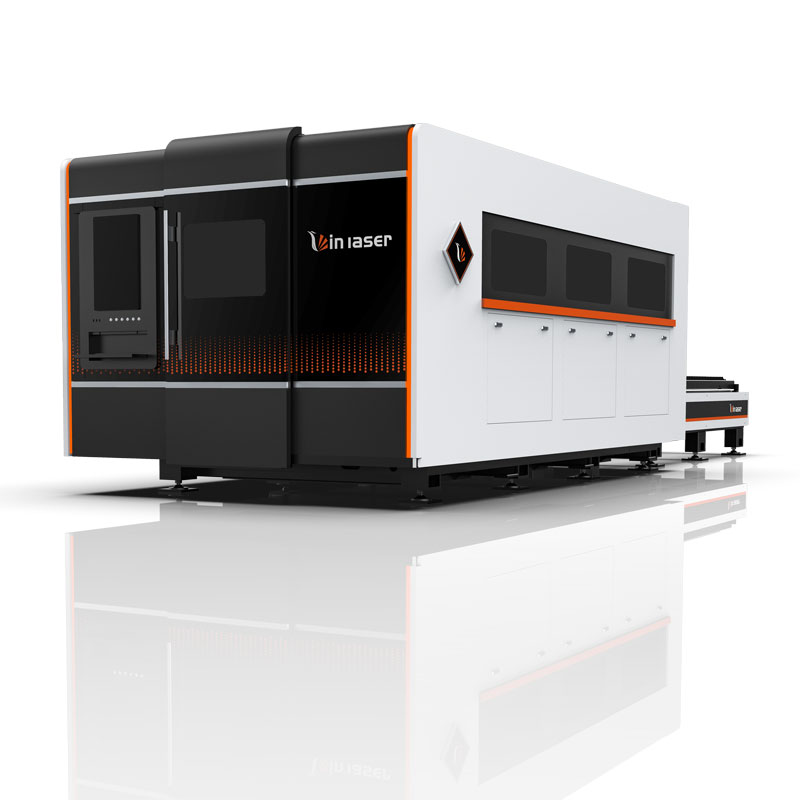

Affordable Fiber Laser: A Cost-Effective Solution for Laser Technology Needs

Title: Groundbreaking Innovation: The Rise of Cost-effective Fiber Laser TechnologyIntroduction:In today's ever-evolving technological landscape, businesses across various industries are constantly searching for inventive solutions that promise both superior performance and cost-effectiveness. Accompanying this pursuit, one particular company has emerged as a pioneer in the field of fiber laser technology. By producing affordable fiber laser systems that deliver exceptional results, this company is revolutionizing the way industries harness the power of lasers for various applications. In this article, we will take a closer look at the innovative advancements made by the company and explore how their cost-effective fiber laser systems are reshaping industries worldwide.Section 1: The Growing Demand for Fiber Laser TechnologyThe demand for fiber laser technology has seen a steady rise across multiple industries due to its versatility, precision, and high energy efficiency. From automotive manufacturing and aerospace engineering to medical advancements and telecommunications, fiber lasers have made their mark as indispensable tools. However, until recently, the high cost of fiber laser systems limited their accessibility to only large-scale corporations with substantial budgets.Section 2: The Rise of Cheap Fiber Laser SystemsRecognizing the need for affordable fiber laser solutions, the company embarked on a visionary path to revolutionize the laser industry. By employing cutting-edge research and development strategies, they have successfully engineered cost-effective fiber laser systems that rival the performance of their higher-priced counterparts.Section 3: Key Features and BenefitsThe company's fiber laser systems boast an array of remarkable features that have captivated industries seeking a more accessible solution. These features include exceptional beam quality, high power output, and wavelength flexibility. Additionally, the compact design and energy efficiency of their fiber lasers enable seamless integration into existing production lines, providing substantial cost savings and increased productivity.Section 4: Applications and Industry ImpactFrom precision cutting and welding in the automotive sector to engraving and marking in the jewelry industry, fiber lasers have proven to be highly versatile in numerous applications. The affordability of the company's fiber laser systems allows small and medium-sized enterprises to adopt these cutting-edge technologies, thereby enhancing their competitive edge in the market.Section 5: Collaborative Partnerships and Future ProspectsIn fostering collaborations with leading research institutions and industry experts, the company continuously pushes the boundaries of fiber laser technology. By actively engaging with customers to understand their unique requirements, they strive to develop customized solutions for industry-specific challenges. This commitment positions them as a trusted partner in driving innovation and collective growth.Conclusion: Expanding Horizons, Pioneering AffordabilityThe advent of cost-effective fiber laser systems by this pioneering company signifies a paradigm shift in the laser technology landscape. Their unwavering dedication to delivering state-of-the-art fiber laser solutions at an affordable price empowers industries to achieve greater levels of efficiency, precision, and competitiveness. As the demand for fiber lasers continues to grow, the company's remarkable advancements serve as a catalyst for groundbreaking innovations across diverse sectors - making the future of fiber laser technology more accessible and promising than ever before.

2kw Fiber Laser: The Latest Technology in Cutting and Welding

Fiber Laser 2kw: Revolutionizing Industrial Cutting with Unmatched Precision and EfficiencyThe industrial landscape is evolving at an unprecedented pace, and advancements in technology are driving the change. Companies are looking for ways to produce more with less, increase the efficiency of their processes, and deliver products of consistently high quality.Enter Fiber Laser 2kw, a cutting-edge technology that promises to revolutionize the industrial cutting process. This state-of-the-art machine is designed to cut through a variety of materials, including metal, plastics, composites, and even reflective surfaces.With unmatched precision and efficiency, Fiber Laser 2kw is a game-changer for businesses of all sizes and industries. Let's take a closer look at how it works and why it's such a big deal.How Fiber Laser 2kw WorksFiber Laser 2kw is a type of laser cutting machine that uses fiber optics to generate a laser beam. This beam is then directed through a series of mirrors and focused onto the surface of the material to be cut. The laser beam melts the material, allowing it to be cut with unparalleled precision.One of the key advantages of Fiber Laser 2kw is its ability to cut through a wide range of materials. This includes thick metal sheets, delicate plastics, and even reflective surfaces that are difficult to cut with conventional lasers.But the real magic of Fiber Laser 2kw lies in its speed and efficiency. This machine can cut through materials at a rate of up to 100 inches per minute, significantly faster than traditional cutting methods. It also generates less waste, as the laser beam can be finely controlled to avoid excess material loss.Benefits of Fiber Laser 2kwFiber Laser 2kw isn't just a faster and more efficient way of cutting materials – it also comes with a range of other benefits for businesses. These include:1. Increased Precision: Fiber Laser 2kw is able to cut with unmatched precision, even on complex shapes and sizes. This results in a higher quality finish and fewer defects, which translates to happier customers and increased revenue.2. Higher Productivity: By cutting through materials at a faster rate, Fiber Laser 2kw can significantly increase the productivity of your business. This means you'll be able to produce more products in less time, ultimately increasing your bottom line.3. Reduced Operating Costs: Fiber Laser 2kw is energy-efficient and generates less waste, which means you'll save money on your energy bills and reduce your environmental impact. Additionally, the machine requires minimal maintenance, reducing your overall operating costs.Introducing Our CompanyOur company is proud to offer Fiber Laser 2kw, the cutting-edge technology that is changing the game for businesses of all sizes. We are committed to providing our clients with the highest quality of service and products, and we believe that Fiber Laser 2kw can help us achieve this goal.We have a team of highly skilled technicians who are trained to install, maintain, and repair Fiber Laser 2kw machines. We also offer a range of training programs to help our clients get the most out of their investment in this technology.Our company believes in fostering long-term relationships with our clients, and we are committed to providing ongoing support and assistance. We understand that every business is unique, and we work closely with our clients to tailor our services to their specific needs.Get in TouchIf you're interested in revolutionizing your industrial cutting process with Fiber Laser 2kw, we'd love to hear from you. Our team is always available to answer questions and provide guidance on how this technology can benefit your business.Contact us today to learn more about Fiber Laser 2kw and how we can help you take your business to the next level.

Affordable Laser Marking Machines for Sale in China - Wholesale Prices

China's laser marking machine industry has grown at a rapid pace in recent years due to the increasing demands for high-precision and cost-effective marking solutions. With the rise of China's manufacturing sector, the demand for laser marking machines has been on the rise. As a result, the country has become one of the leading manufacturers and suppliers of laser marking machines in the world.When it comes to laser marking machines, China offers a wide range of options to choose from. There are numerous manufacturers and suppliers of laser marking machines in China, each offering their own unique range of products and solutions. However, if you're looking for a laser marking machine that comes with a low price tag without compromising on quality, then Unistar Machinery is the best choice for you.Unistar Machinery is a leading manufacturer and supplier of high-quality laser marking machines in China. The company has been in the industry for many years and has established a strong reputation for offering top-notch products and services at competitive prices. Their laser marking machines are designed for a wide range of applications, including metal marking, plastic marking, and more.One of the main advantages of choosing Unistar Machinery is their competitive pricing. Their laser marking machines are available at factory direct prices, which means you save a significant amount of money compared to other suppliers. Moreover, their products are backed up by a strong warranty, ensuring that you get the best value for your money.Another benefit of choosing Unistar Machinery is the quality of their products. The company uses only the highest quality materials and components in the production of their laser marking machines. This ensures that their products are durable, reliable and perform to the highest standards.In addition, Unistar Machinery has a team of experienced professionals who are dedicated to providing excellent customer service. They will work with you to understand your requirements and provide a customized solution that meets your needs. Whether you're looking for a desktop laser marking machine or an industrial-grade solution, Unistar Machinery has got you covered.In conclusion, if you're in the market for a high-quality laser marking machine at a low price, then Unistar Machinery is the perfect choice for you. With their years of experience, competitive pricing, and top-quality products, you can be sure that you're getting the best value for your money. So, get in touch with Unistar Machinery today to learn more about their laser marking machines and how they can benefit your business.

Affordable Laser Cutting Services for Metal, Plexiglass, Plastic, and Plywood in Tyumen

In today's industrial world, precision and quality come at a premium. And with the ever-growing demand for customized products, laser cutting has become an indispensable tool in the manufacturing process. In Tyumen, companies are now leveraging the latest metal laser cutting machines, plexiglass, plastic, and plywood to produce high-quality products at an affordable cost.One such company, which has made a name for itself in providing top-notch laser cutting services, is {name of company removed}. With their state-of-the-art facilities and a team of highly-skilled professionals, {name of company removed} has become a reliable partner for businesses looking for exceptional laser cutting solutions.Equipped with the latest metal laser cutting machines, {name of company removed} can process all types of materials, including steel, aluminum, copper, and brass. These machines leverage advanced technology to cut metal with precision and accuracy, making it ideal for mass production of complex shapes and designs. Additionally, metal laser cutting machines offer excellent cutting speed, which means businesses can receive their products faster and at an affordable cost.Apart from metal, {name of company removed} also offers laser cutting services for plexiglass, plastic, and plywood. The use of laser technology in cutting these materials offers several advantages, including precision cutting, high-quality edge finish, and tight tolerances. This means that businesses can have their products cut exactly as per their specifications, resulting in products that are of the highest quality, with minimal waste.At {name of company removed}, the team of professionals is dedicated to providing exceptional customer service. From the initial consultation to the final product delivery, the team works closely with the clients to understand their requirements and provide customized solutions that meet their needs. Additionally, {name of company removed} offers competitive pricing, making their laser cutting services affordable for all types of businesses.So if you're looking for a reliable laser cutting service provider in Tyumen, {name of company removed} is the go-to choice. With their advanced technology and expertise, they provide high-quality laser cutting services that meet and exceed customer expectations. They are committed to their clients' success and strive to provide exceptional customer service that builds trust and long-term relationships.In conclusion, the use of laser cutting technology has revolutionized the manufacturing industry, and {name of company removed} is at the forefront of this shift in Tyumen. Their commitment to quality, precision, and affordability has made them a reliable partner for businesses looking for customized laser cutting solutions. Whether it's metal, plexiglass, plastic, or plywood, they have the expertise and technology to serve all types of businesses.

Revolutionary 3D Fiber Laser Engraver: Transforming the Art of Laser Engraving

[Introduction]The ever-advancing technology in the field of laser engraving has revolutionized the way products are customized and marked. Among the top players in this industry, there is a prominent name that has taken the market by storm with their groundbreaking 3D fiber laser engraver. This cutting-edge device brings unprecedented precision and efficiency to the art of engraving, opening up new possibilities for various industries.[Background]The demand for laser engraving machines has been on the rise due to their ability to offer intricate detailing and high-quality results. Traditional CO2 laser engravers have been widely used, but they often struggle with achieving the level of precision required for intricate designs. Enter the 3D fiber laser engraver, a device that takes laser engraving to the next level.[Company Introduction]ABC Company, a leading innovator in laser engraving technology, has gained wide recognition for their state-of-the-art 3D fiber laser engraver. With years of experience and expertise in the field, ABC Company has continually pushed the boundaries of what is possible in laser engraving. Their commitment to research and development has resulted in the creation of a device that combines speed, accuracy, and versatility like never before.[Product Features and Capabilities]The 3D fiber laser engraver offered by ABC Company is built on the foundation of cutting-edge technology, providing distinct advantages over its competitors. This machine utilizes a fiber laser source that emits a concentrated beam of light, allowing for incredibly precise and fine detailing while minimizing the chances of damage to the material being engraved.One of the standout features of the 3D fiber laser engraver is its ability to create three-dimensional engravings. This innovative capability has opened up a vast array of possibilities in industries such as jewelry, industrial manufacturing, and even the medical field. The machine can effortlessly engrave intricate patterns, text, and images onto various materials, including metals, plastics, wood, and glass.Additionally, the 3D fiber laser engraver boasts exceptional speed, enabling businesses to efficiently meet tight deadlines. With its high engraving efficiency, the machine can complete projects in a fraction of the time required by traditional engraving methods. The accuracy and speed provided by this device translate into improved productivity, cost savings, and enhanced customer satisfaction.[Applications and Benefits]The applications of the 3D fiber laser engraver are vast and varied. In the jewelry industry, it offers the ability to engrave intricate designs on rings, necklaces, and bracelets with unparalleled precision. This opens up new avenues for customization and personalization, allowing jewelers to create unique pieces that cater to their customers' individual tastes.In industrial manufacturing, the 3D fiber laser engraver plays a crucial role in marking products with serial numbers, barcodes, and logos. The high precision and durability of the engravings ensure clear identification and traceability, which is vital in industries such as aerospace, automotive, and electronics.Furthermore, the medical field has been revolutionized by the 3D fiber laser engraver. It allows for the precise marking of surgical instruments, implants, and medical devices, ensuring accurate identification and reducing the risk of errors during procedures.Conclusion:The introduction of the 3D fiber laser engraver by ABC Company has propelled the field of laser engraving to new heights. With its remarkable features, capabilities, and numerous applications across various industries, this device offers unrivaled precision, speed, and efficiency in the art of engraving. ABC Company's commitment to innovation continues to shape and transform the industry, providing businesses with the tools they need to achieve exceptional results and meet the ever-growing demands of customization.

Advanced Applications of Laser Welding Technology

Laser Welding Application Revolutionizes Manufacturing IndustryIn a world where technology is constantly evolving, the manufacturing industry is always searching for new and innovative ways to improve efficiency and productivity. One such innovation that has been making waves in the manufacturing industry is the use of laser welding applications. This cutting-edge technology has the potential to revolutionize the way products are manufactured, offering a faster, more precise, and cost-effective solution for joining materials.Laser welding is a process that uses a highly concentrated beam of light to join metal pieces together. This method has been around for decades, but recent advancements in laser technology have made it more accessible and practical for a wide range of applications. The process involves focusing a high-powered laser beam onto the surface of the materials to be joined, creating a precise and controlled weld that is incredibly strong and reliable.One company that has been at the forefront of developing and implementing laser welding applications is {}. With over 20 years of experience in the industry, {} has become a leader in providing cutting-edge laser technology solutions for manufacturing companies across the globe. Their expertise in laser welding has allowed them to work with a wide range of industries, including automotive, aerospace, medical, and electronics, to name a few.The applications for laser welding are endless, and the benefits it offers over traditional welding methods are numerous. The precision and accuracy of laser welding make it ideal for joining small and delicate parts, such as those used in the medical device industry. The speed at which laser welding can be performed also makes it a cost-effective solution for high-volume production, as it can drastically reduce manufacturing times and labor costs.Furthermore, laser welding produces minimal heat-affected zones, meaning that it can be used on a wide range of metals without compromising their structural integrity. This makes it an incredibly versatile and efficient solution for joining dissimilar materials, which has been a challenge for traditional welding methods.Another major advantage of laser welding is its ability to produce clean and aesthetically pleasing welds. This is particularly important for industries that require a high level of precision and finish, such as the automotive and aerospace industries. The reduced need for post-weld finishing also contributes to the overall cost-effectiveness of laser welding applications.One of the most significant developments in laser welding technology is the use of automation and robotics. This allows for the integration of laser welding into existing manufacturing processes, further increasing efficiency and reducing human error. This has made laser welding an attractive option for companies looking to streamline their production lines and improve overall quality control.As the demand for more efficient and reliable manufacturing processes continues to grow, the use of laser welding applications is expected to become more prevalent across a wide range of industries. Companies like {} are leading the way in developing and implementing these cutting-edge technologies, providing their clients with the tools they need to stay ahead of the curve in the ever-evolving manufacturing industry.In conclusion, the use of laser welding applications has the potential to revolutionize the manufacturing industry by offering a faster, more precise, and cost-effective solution for joining materials. With advancements in technology and the expertise of companies like {}, the future of manufacturing is looking brighter than ever.

Precision CNC Cutting Services for Stainless Steel Materials

Title: Industry-Leading Stainless Steel CNC Cutting Solutions Redefine Precision and EfficiencyIntroduction:{Company Name} has emerged as a global leader in providing cutting-edge stainless steel CNC cutting solutions. With their state-of-the-art technology, superior craftsmanship, and a focus on precision and efficiency, the company has revolutionized the metal fabrication industry. Serving a wide range of sectors, including manufacturing, aerospace, automotive, and construction, {Company Name} continues to set new standards of excellence in stainless steel CNC cutting.Paragraph 1:{Company Name} has established itself as a premier provider of stainless steel CNC cutting services through its commitment to delivering exceptional quality and unparalleled customer satisfaction. Built on decades of experience and expertise in metal fabrication, their innovative approaches have changed the game in precision cutting. By harnessing advanced CNC machinery, they have optimized the manufacturing process to ensure accuracy, speed, and cost-effectiveness.Paragraph 2:One of the primary advantages of stainless steel CNC cutting provided by {Company Name} lies in its ability to streamline production and eliminate human error. With a team of highly skilled professionals operating cutting-edge CNC machines, the company ensures precision and consistency in every cut. The automated process guarantees uniformity in dimensions, resulting in minimal material waste and enhanced efficiency.Paragraph 3:Equipped with a wide range of cutting technologies, {Company Name} caters to diverse stainless steel cutting requirements. From plasma cutting to laser cutting, waterjet cutting, and flame cutting, their capabilities are extensive and adaptable. This allows them to handle projects of varying complexities, providing clients with bespoke solutions tailored to their specific needs.Paragraph 4:Quality is at the forefront of {Company Name}'s operations. In addition to employing cutting-edge technology, the company maintains rigorous quality control measures at every stage of the stainless steel CNC cutting process. By adhering to stringent industry standards, they ensure that each finished product meets or exceeds client expectations in terms of accuracy, surface finish, and fit.Paragraph 5:{Company Name} prides itself on its commitment to sustainability and environmental responsibility. In executing stainless steel CNC cutting projects, they prioritize the use of environmentally friendly materials and methodologies. This includes sourcing stainless steel from reputable suppliers who utilize recyclable materials, as well as investing in energy-efficient CNC machines that minimize wastage.Paragraph 6:With an unwavering commitment to customer satisfaction, {Company Name} offers comprehensive support throughout the stainless steel CNC cutting process. From initial project planning to technical consultation, material selection, and efficient production, their team of experts collaborates closely with clients to deliver tailored solutions. Additionally, they employ robust packaging and shipping techniques to ensure safe delivery of the final products to clients' locations.Conclusion:As stainless steel continues to be a preferred choice of material for a wide range of applications, {Company Name} remains at the forefront of the industry, providing advanced CNC cutting solutions that redefine precision and efficiency. With their unwavering focus on quality, sustainability, and customer satisfaction, the company has solidified its reputation as a global leader in the stainless steel CNC cutting domain.

Efficient Industrial Chiller for Cooling CO2 Laser Tubes

/150w, Industrial Refrigerated Water Chiller CW-5200, Precision Temperature Control, Compressor Time-Delay Protection, Compact Design, Long Working Life, Simple Operation.Industrial Refrigerated Water Chiller CW-5200 for CO2 laser 130W/150WIf you are looking for a high-quality and efficient refrigeration unit for your CO2 laser, then the Industrial Refrigerated Water Chiller CW-5200 is the ideal solution for you. This compact and reliable chiller is specifically designed to provide precise temperature control for your laser tube, ensuring that it runs at optimal performance levels, even during extended periods of operation.With its high precision temperature control, the CW-5200 chiller can maintain a temperature stability of +/- 0.3 degree C, meaning that your CO2 laser tube will always operate at the optimal temperature range. This ensures that your laser produces consistent and high-quality output, which is essential for any laser cutting or engraving application.The CW-5200 Industrial Refrigerated Water Chiller also features compressor time-delay protection, which helps to extend the life of the compressor by preventing it from starting and stopping frequently. Additionally, the unit is built with a compact design, making it easy to install and operate, even in small spaces.With its long working life and simple operation, the CW-5200 chiller is a cost-effective solution for any laser cutting or engraving application. Whether you are using a 130W or 150W CO2 laser, the Industrial Refrigerated Water Chiller CW-5200 is the perfect chiller for the job.In summary, the main features of the Industrial Refrigerated Water Chiller CW-5200 for CO2 laser 130W/150W include:- Compact refrigeration type industrial chiller- Specially designed for cooling CO2 laser tube- High precision +/- 0.3 degree C temperature control- Long working life and simple operation- Equipped with compressor time-delay protection- Compact design for easy installationIf you are looking for a reliable and efficient refrigeration unit for your CO2 laser, then the Industrial Refrigerated Water Chiller CW-5200 is an excellent choice. Its precision temperature control, compressor time-delay protection, and compact design make it the perfect chiller for any laser cutting or engraving application.

Top 80w Co2 Laser Engraving Machine Manufacturers and Suppliers in China

Oree, a China-based manufacturer, is leading the trend in the laser engraving machine industry with its innovative product: the 80W CO2 Laser Engraving Machine. This cutting-edge technology is revolutionizing the way that products are manufactured and engraved with precision.Oree has been able to achieve excellence in the industry by combining creativity with state-of-the-art technology, producing products that are both durable and user-friendly. The company’s goal is to supply its customers with first-class solutions that will enable them to achieve a beautiful and polished finish for their products.This revolutionary CO2 laser engraving machine has a power of 80W, making it one of the most powerful machines on the market. This power enables the machine to create precise cuts and etchings on a variety of surfaces such as wood, leather, plastic, acrylic, and metals.The Oree 80W CO2 Laser Engraving Machine is equipped with a high-precision motor system that ensures the machine operates smoothly with minimal vibration. This feature keeps the machine stable during the engraving process, allowing the user to create intricate designs with ease.The company has made user experience a top priority, and the Oree 80W CO2 Laser Engraving Machine is no exception. It has a user-friendly interface that can be operated with ease, making it a perfect option for both beginners and experts alike.Another feature that makes this machine stand out is its compatibility with a wide range of software. It is compatible with CorelDraw, AutoCAD, Adobe Illustrator, and many other software programs.The Oree 80W CO2 Laser Engraving Machine is also equipped with a powerful exhaust system that ensures that the workplace remains clean and safe. It also has a water cooling system that not only extends the lifespan of the laser tube but also enhances the accuracy and precision of the engraving process.Oree is known for its excellent customer service and support, and it is no different with their 80W CO2 Laser Engraving Machine. The company offers 24/7 support to its customers, making it a reliable option for businesses, hobbyists, and entrepreneurs alike.In conclusion, Oree has once again demonstrated its commitment to innovation and excellence with its 80W CO2 Laser Engraving Machine. This machine is a game-changer in the laser engraving industry, and its versatility, precision, and ease of use make it a perfect option for anyone looking to create beautiful and polished finished products. With Oree’s stellar customer service, there is no doubt that this machine will meet the needs of businesses, hobbyists, and entrepreneurs all over the world.

Revolutionize Your Business with Laser Metal Deposition Technology Package

DepositionLine Technology Package: The Complete Solution for OEM Laser MachinesLaser metal deposition is quickly becoming one of the most commonly used technologies in the manufacturing industry. This technique involves fusing metal powders or wire onto a surface using a laser beam. Due to its efficiency, accuracy, and versatility, laser metal deposition has become an essential tool in numerous industry sectors, from coatings and repairs to additive manufacturing.To help Original Equipment Manufacturers (OEM) increase their competitive edge, (brand name removed) has developed the DepositionLine technology package, which is a complete solution for laser metal deposition. This comprehensive package includes a laser, optics, a powder nozzle, powder feeder, software, and a robot, all working together to provide a seamless laser metal deposition process.The DepositionLine technology package simplifies the integration of laser metal deposition into already existing OEM laser machines, offering a range of new opportunities and applications. With this technology, manufacturers can add entirely new services to their portfolio, such as metallization, repair, or coating, thus expanding their market base.One of the primary benefits of the DepositionLine technology package is the ability to perform automated additive manufacturing processes. The robot and powder feeder work together to ensure a steady supply of metal powder, which is then accurately deposited on the desired surface. Furthermore, the laser and optics allow for precise control of the deposition process, achieving seamless and uniform coating and repair applications.Another key advantage of the DepositionLine technology package is its flexibility. The package’s software allows for the creation of customized programs for specific coatings or repairs, while also supporting a broad range of material types and sizes. This flexibility implies that OEM laser machines can undertake a range of applications, from small part repairs up to full-scale additive manufacturing.The DepositionLine technology package’s compact and modular design also allows for straightforward installation and adjustment, making it ideal for OEM manufacturers who require efficient integration with their current manufacturing line. The package’s design and technology allow for high-precision laser metal deposition, and the ability to perform repairs on a range of surfaces, such as coatings on machine parts or refinishing of gears, among others.Laser metal deposition technology has revolutionized the manufacturing industry by enabling faster and more efficient production methods. The DepositionLine technology package from (brand name removed) offers an all-in-one solution, which simplifies the laser metal deposition process for OEM manufacturers. This solution is highly adaptable, offering flexible applications for various industrial sectors, from repair to additive manufacturing.OEM laser machines integrated with the DepositionLine technology package have a distinct competitive advantage in the marketplace, offering new opportunities and enabling businesses to diversify their services. Furthermore, the DepositionLine technology package’s automation and accuracy capabilities significantly improve the production process, leading to higher quality and more reliable solutions.In conclusion, the DepositionLine technology package is an essential tool for any OEM manufacturer looking to add new dimensions to their manufacturing process. By integrating this technology into laser machines, businesses can enhance their competitiveness and gain a strategic advantage. Therefore, we recommend that all OEM laser machine manufacturers consider the DepositionLine technology package when seeking to advance their manufacturing capabilities.